Polyvinyl Alcohol (PVA)-based Glycol Nanohydrogel Production Service

Properties of Polyvinyl Alcohol (PVA)

PVA is a water-soluble long-chain polymer obtained by alcoholysis, hydrolysis, or aminolysis of polyvinyl acetate (PVAc). Its molecular chain contains a large number of hydroxyl groups, which provide abundant reaction sites for chemical modification. PVA is cheap and easy to obtain and has good biocompatibility, mechanical properties, and excellent film-forming properties. Therefore, PVA is the first choice for constructing polymer hydrogel materials and has great application potential in the development of drug carriers, tissue engineering scaffolds, and organ materials. CD BioGlyco has specially developed a

GlycoNano™ Platform for researching and developing the application of nanomaterials in the biomedical field, such as

Glyconanoparticle Development,

Glycol Nanohydrogel Development, etc. With this advantageous platform, we provide clients with worry-free PVA-based glycol nanohydrogel production services.

Fig.1 The synthesis route and chemical structure of PVA. (Liang, et al., 2024)

Fig.1 The synthesis route and chemical structure of PVA. (Liang, et al., 2024)

Elevate Your Projects with Our Advanced PVA-based Hydrogel Solutions!

Polymer hydrogel networks are low-crosslinked materials that are formed into a certain shape under natural conditions and show good flexibility under certain pressures. This type of functional polymer material with functional properties such as water absorption, water retention, and controlled release has been greatly welcomed. PVA-based hydrogels are colloidal dispersions with a three-dimensional network structure formed by crosslinking and swelling. They have the advantages of low toxicity, high water absorption, good mechanical properties, and good biocompatibility. We use advanced technology to help clients prepare and modify PVA-based hydrogels. Our services are as follows:

Preparation of PVA Hydrogels

- Physically crosslinked PVA gels: PVA molecular chains are connected by physical interactions (such as hydrogen bonds, van der Waals forces, etc.) to form a three-dimensional network structure. This method is usually mild and has little effect on the structure of the PVA molecular chains. The repeated "freeze-thaw method" is the most commonly used physical crosslinking process, changing the solvent type or using a mixture of dimethyl sulfoxide (DMSO) and water to improve the gelation performance.

- Chemically crosslinked PVA gels: By introducing a crosslinking agent, covalent bonds are formed between PVA molecular chains, thereby constructing a stable three-dimensional network structure. Chemical crosslinking is the most commonly used method for preparing hydrogels. The properties of hydrogels are affected by monomer concentration, crosslinking agent, and reaction conditions. Commonly used crosslinking agents include epichlorohydrin, boric acid, aldehydes, heavy metal compounds, etc.

- PVA gels crosslinked by radiation: PVA aqueous solution is irradiated by high-energy rays (such as gamma rays, electron beams, X-rays, etc.) to generate free radicals in the PVA molecular chains. These free radicals react with each other or with other substances in the solution to form a crosslinked network. This method has the advantages of being fast, efficient, and pollution-free. PVA hydrogels produced by radiation do not contain crosslinking agents, so they have high purity and good optical transparency.

Modification of PVA Hydrogels

- Chemical modification: By introducing functional groups or polymer chains, the chemical structure of the PVA molecular chain is changed, thereby giving the hydrogel new properties. Chemical modification significantly improves the properties of PVA hydrogels, making them promising for use in biomedicine, drug delivery, tissue engineering, and other fields.

- Physical modification: The properties of the hydrogel are changed by changing the spatial arrangement of the PVA molecular chains or introducing other substances without changing the chemical structure of the PVA molecular chains.

- Filler reinforcement: Fillers are introduced into PVA hydrogel to improve the mechanical properties, flame retardancy, conductivity, etc.

Workflow

Applications

- PVA hydrogel is used to develop drug carriers and embeds small drug molecules to increase the stability of drugs.

- PVA hydrogel is used as wound dressing material to reduce external environmental stimulation, promote the growth of new tissues, and promote wound healing.

- PVA hydrogel material has a porous and permeable structure similar to natural cartilage and contains a large amount of water. It is a potential candidate material for the development of tissue scaffolds.

Advantages

- With the advantage of the GlycoNano™ platform, we provide clients with PVA hydrogel material preparation services using physical cross-linking, chemical cross-linking, and radiation technology.

- We modify PVA hydrogel materials through physical, chemical, and filler methods to enhance their physical and chemical properties.

- We help clients develop PVA hydrogel materials for multiple fields, such as drug delivery, tissue engineering, etc.

Publication Data

DOI: 10.1016/j.polymertesting.2022.107516

Journal: Polymer Testing

Published: 2022

IF: 5.0

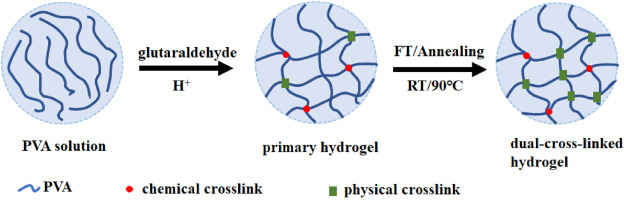

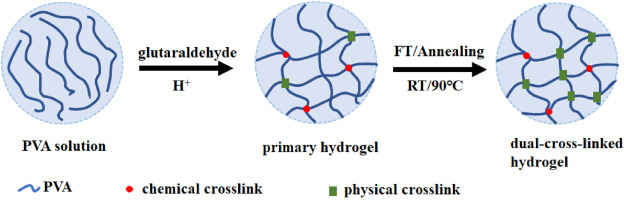

Results: The authors developed a method to prepare high-strength and tough PVA hydrogels by physical and chemical dual crosslinking and studied the effects of various factors on the mechanical properties of the hydrogels. The results showed that the best comprehensive mechanical properties could be obtained by reacting at room temperature followed by freeze-thaw and annealing treatment, with tensile strength and toughness of 14.48 MPa and 96.60 MJ/m3, respectively. When the molecular weight was 145,000 and the mass fraction was 10%, the comprehensive mechanical properties of the PVA hydrogel material were the best. Changing the reaction solvent effectively adjusted the mechanical properties of the PVA hydrogel. The hydrogel obtained with water as the solvent showed the highest mechanical strength, and ethylene glycol improved the toughness of the PVA hydrogel.

Fig.2 Schematic synthesis of PVA hydrogel with high strength and toughness. (Chen, et al., 2022)

Fig.2 Schematic synthesis of PVA hydrogel with high strength and toughness. (Chen, et al., 2022)

Frequently Asked Questions

- What customizations are available for the hydrogel formulation?

Clients request modifications in terms of hydrogel strength, flexibility, degradation rates, and specific release profiles to suit particular application needs.

-

What quality controls are in place for the production process?

We implement strict quality control measures to ensure the product standards of PVA hydrogel. Standardized tests are first used to ensure that materials meet predefined specifications. During the production process, reaction conditions are monitored and controlled in real time. Finally, the product is subjected to a series of tests to check its uniformity, stability, particle size distribution, and other relevant physical and chemical characteristics.

CD BioGlyco provides high-quality, professional PVA-based glycol nanohydrogel production services to meet a variety of scientific and commercial needs. Our services cover the entire process from custom formulation design to final product delivery, ensuring the excellent performance and reliability of the product. Welcome clients to feel free to contact us for more detailed service information.

References

- Chen, Y.; et al. Synthesis and properties of poly (vinyl alcohol) hydrogels with high strength and toughness. Polymer Testing. 2022, 108: 107516.

- Liang, X.; et al. Polyvinyl alcohol (PVA)-based hydrogels: Recent progress in fabrication, properties, and multifunctional applications. Polymers. 2024, 16(19): 2755.

This service is for Research Use Only, not intended for any clinical use.

Fig.1 The synthesis route and chemical structure of PVA. (Liang, et al., 2024)

Fig.1 The synthesis route and chemical structure of PVA. (Liang, et al., 2024)

Fig.2 Schematic synthesis of PVA hydrogel with high strength and toughness. (Chen, et al., 2022)

Fig.2 Schematic synthesis of PVA hydrogel with high strength and toughness. (Chen, et al., 2022)