PEG-modified upconversion nanoparticles (UCNPs) combine the unique optical properties of upconversion materials with the beneficial properties of polyethylene glycol (PEG) modification. The upconversion properties enable the nanoparticles to convert low-energy infrared light into high-energy visible light, opening up several applications in areas such as bioimaging, biosensing, and photodynamic therapy. The PEG modification enhances the nanoparticle's biocompatibility and stability in biological systems. The PEG helps to minimize non-specific interactions and immune responses and prolongs nanoparticle circulation time in vivo. This modification also improves the solubility and dispersion of nanoparticles, facilitating their delivery and targeting to specific sites. In research and potential clinical applications, PEG-modified UCNPs provide a powerful tool for researchers to explore and develop novel therapeutic strategies and imaging techniques.

CD BioGlyco has made significant advancements in the GlycoNano™ Platform, enabling us to offer a comprehensive range of professional services. These services include not only Glyconanoparticle Development Service, Glycol Nanohydrogel Development Service, and Glycol Nanorod Production Service, but also several other specialized offerings. Among them, our PEG Glyconanoparticle Production Service has gained wide acclaim and popularity among our customers. This service is renowned for its high quality, efficiency, and precision, which have met and exceeded the expectations of our clients. The details of our PEG-modified UCNPs production service are as follows.

Firstly, we synthesize UCNPs with an inorganic core@shell structure where the core is Yb3+ and Tm3+ doped NaYF4 and the shell is NaYF4. Subsequently, the surface modification is carried out and the synthesized UCNPs are intercalated using the amphiphilic polymer. The amphiphilic polymer (e.g. PMAO) can be coated on the surface of UCNPs through the solvent evaporation technique. Next, cross-linking is performed using poly(ethylene glycol) diglycol ether (PEG-DGE). PEG-DGE with a molecular weight of 500 is selected to form a "core-crown" structure. The aqueous dispersion containing UCNPs is centrifuged and resuspended in PBS buffer, and a certain amount of aqueous PEG-DGE is added. The mixture undergoes vortexing, sonication, heating, and stirring. Finally, the mixture is centrifuged once again to remove unreacted cross-linkers and the precipitate is resuspended in PBS buffer.

In characterizing PEG-modified UCNPs, we use transmission electron microscopy (TEM) to image UCNPs. Samples are observed by dilution, sonication, and dropwise addition to a copper grid coated with 0.3% pioloform. This method provides information on the morphology and size of the nanoparticles. We analyze the pure UCNPs and their modified samples with PMAO and PEG-DGE by using Fourier transform infrared spectroscopy (FTIR), which can help to confirm the presence of PEG-modified chemical structures and functional groups.

Our experts determine the concentration of non-adsorbed serum proteins in the presence of UCNPs by the Bradford method to assess the interaction of UCNPs with biological fluids. We analyze blood samples using a customized anti-Stokes fluorescence microscope to observe the distribution and amount of UCNPs in the blood.

The workflow of our PEG-modified UCNP production is shown below.

Technologies: TEM, X-ray diffraction (XRD), Scanning electron microscopy (SEM), Atomic force microscopy (AFM)

Journal: Chemical Society Reviews

Published: 2015

IF: 40.4

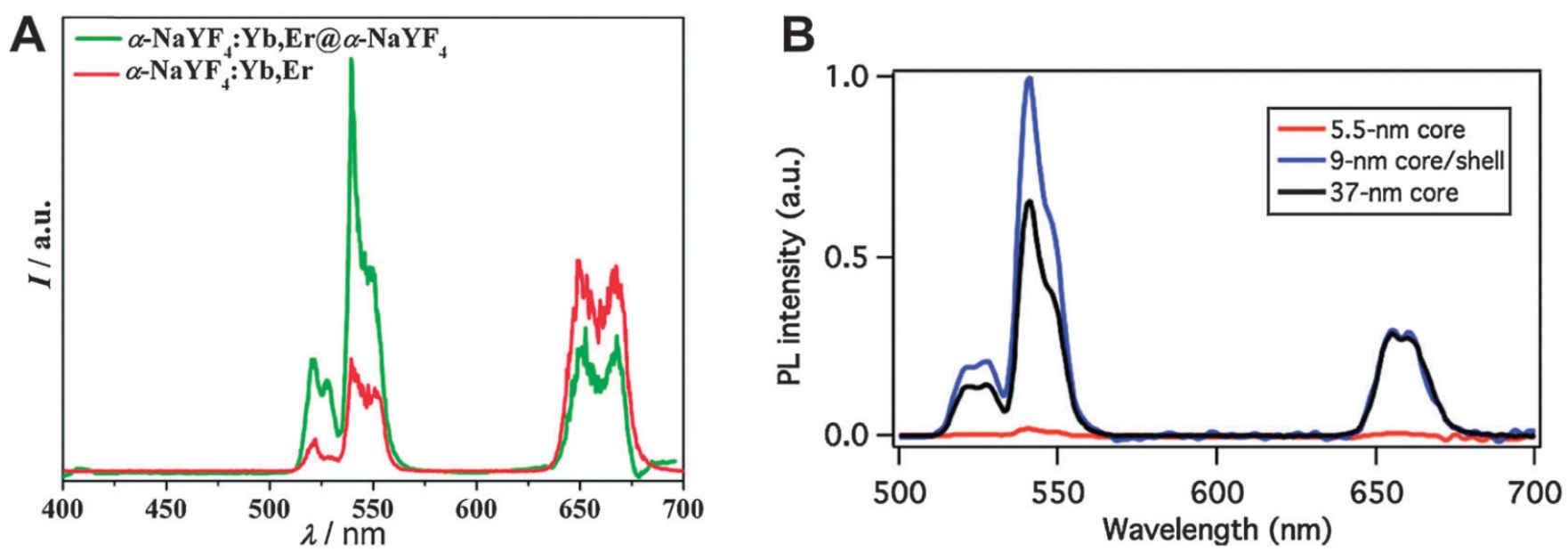

Results: The main research of this article is about the surface modification of photonic UCNPs and their characterization for bioanalytical applications. The ability of UCNPs to be excited by near-infrared light and to emit visible light enables them to exhibit low autofluorescence and light scattering in biological samples, thus showing a wide range of potential applications in background interference-free imaging. Surface modification methods for photonic UCNPs mentioned in the article include ligand exchange, ligand modification, ligand interaction, and layer deposition. In addition, the article discusses different analytical methods for assessing the progress and success of surface functionalization, including nuclear magnetic resonance (NMR) techniques, UV absorption spectroscopy, chromatographic reagents, and fluorescent labeling.

Fig.1 The impact of a core-shell design on the upconversion luminescence of NaYF4:Yb,Er nanocrystals under 980 nm excitation. (Sedlmeier & Gorris, 2015)

Fig.1 The impact of a core-shell design on the upconversion luminescence of NaYF4:Yb,Er nanocrystals under 980 nm excitation. (Sedlmeier & Gorris, 2015)

CD BioGlyco is dedicated to offering you the outstanding PEG-modified UCNPs production service. Our devoted team, equipped with vast knowledge and sophisticated techniques, has a strong passion for creating high-quality PEG-modified UCNPs. If you are interested in our service, please contact us without any restraint!

Reference